In geotechnical engineering, the direct shear test is one of the most widely used experiments for determining the shear strength of soil. It provides engineers with valuable information about how soil will behave when subjected to forces that attempt to slide one layer over another. This knowledge is critical for designing foundations, retaining walls, embankments, and slopes. Understanding the principles behind the direct shear test helps ensure safer and more reliable structures in construction projects of all sizes. While the test appears simple, it offers insights into complex soil behavior that can directly influence engineering decisions.

Definition of the Direct Shear Test

The direct shear test is a laboratory method used to measure the shear strength parameters of soil, specifically cohesion and the angle of internal friction. These properties describe how soil resists shearing forces and are essential for predicting stability. In the test, a soil sample is placed inside a shear box, which is then split horizontally into two halves. A vertical load is applied to simulate normal stress, and a horizontal force is gradually increased until the soil fails along the plane between the two halves. The maximum resistance recorded during this process represents the soil’s shear strength.

Importance of Shear Strength in Soil

Shear strength is one of the most important properties of soil because it governs the stability of geotechnical structures. When engineers design slopes, retaining walls, or foundations, they must consider how much shear stress the soil can withstand before failure. If shear strength is underestimated, structures may collapse due to landslides, settlement, or bearing capacity failure. By using the direct shear test, engineers can make more accurate calculations, leading to safer and more cost-effective designs.

Apparatus Used in Direct Shear Test

The equipment for a direct shear test is relatively straightforward but carefully designed to ensure accurate measurements. The main components include

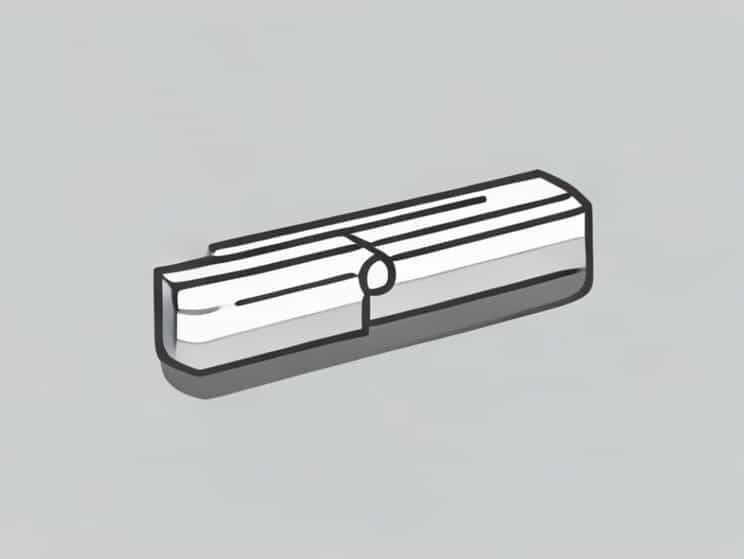

- Shear boxA square or circular container divided into upper and lower halves where the soil specimen is placed.

- Loading systemApplies normal stress vertically on the sample to simulate overburden pressure.

- Shearing mechanismMoves the lower half of the box horizontally to apply shear force.

- Dial gaugesMeasure horizontal displacement, vertical displacement, and applied loads.

- Proving ring or load cellRecords the shear force applied to the specimen.

Procedure of the Direct Shear Test

The testing process follows a series of systematic steps to ensure reliable results. The general procedure includes

- Prepare the soil specimen, usually 60 mm à 60 mm in size, either undisturbed or compacted depending on the purpose of the test.

- Place the specimen in the shear box and secure it with porous plates and a grid plate.

- Apply a vertical load to simulate the normal stress acting on the soil in the field.

- Allow the sample to consolidate under the applied load, especially in the case of saturated soils.

- Gradually apply horizontal shear force by moving the lower half of the box at a controlled rate.

- Record the shear force and corresponding displacement until the soil reaches failure.

- Repeat the test under different normal stresses to develop a failure envelope and determine shear strength parameters.

Parameters Obtained from the Test

From the direct shear test, two main shear strength parameters are derived using Mohr-Coulomb’s failure criterion

- Cohesion (c)The component of shear strength independent of normal stress, representing the natural bonding between ptopics.

- Angle of internal friction (Ï)Represents the resistance due to interlocking of ptopics and friction between them.

The relationship is expressed as Ï = c + Ï tanÏ, where Ï is shear strength and Ï is normal stress.

Advantages of the Direct Shear Test

Despite its simplicity, the direct shear test has several advantages that make it popular in soil mechanics laboratories

- Simple setup and easy to perform.

- Relatively quick results compared to more complex tests.

- Provides a direct measurement of shear strength on a predefined plane.

- Useful for sandy soils and coarse-grained materials where drainage is easier to control.

Limitations of the Direct Shear Test

While widely used, the test does have limitations that engineers must consider when interpreting results

- The shear plane is predetermined, which may not represent the weakest plane in natural soil conditions.

- Non-uniform stress distribution can occur along the shear plane.

- It is less accurate for cohesive soils, where pore pressure and consolidation behavior are complex.

- Soil disturbance during sample preparation can affect results.

Types of Direct Shear Tests

Depending on how drainage conditions are controlled, the direct shear test can be performed in different modes

- Drained testAllows full drainage during loading, commonly used for sandy soils.

- Consolidated undrained testPermits drainage during normal load application but prevents drainage during shearing.

- Undrained testNo drainage is allowed throughout, often used for saturated clays where rapid loading is simulated.

Applications of the Direct Shear Test

The test plays a vital role in many areas of geotechnical engineering. Its results are used in the design and analysis of

- Retaining walls and their backfill stability.

- Slopes and embankments to evaluate risk of landslides.

- Foundations to assess bearing capacity.

- Pavements where soil strength affects performance.

Comparison with Other Shear Tests

Other tests, such as the triaxial shear test, also measure soil strength but with more controlled conditions. Compared to triaxial tests, the direct shear test is simpler and faster, though less precise. Triaxial tests allow measurement of pore water pressure and stress-strain behavior in more detail. However, for preliminary investigations and sandy soils, the direct shear test remains highly effective.

Recent Advances in Shear Testing

Modern geotechnical laboratories are enhancing the accuracy of direct shear testing with automated systems. These systems use electronic sensors, computerized data acquisition, and servo-controlled loading devices. This reduces human error, ensures more consistent test speeds, and provides detailed data analysis. Advances in software also allow engineers to model soil behavior more accurately based on direct shear test data.

The direct shear test remains a fundamental method in soil mechanics for determining shear strength parameters. Despite certain limitations, it provides essential data for geotechnical design and construction. By understanding how to perform the test, interpret results, and recognize its advantages and drawbacks, engineers can make better decisions when analyzing soil stability. Whether used for simple field investigations or detailed laboratory studies, the direct shear test continues to be a cornerstone in ensuring the safety and reliability of engineering projects.